Research Project DEPOT

The aerospace industry has always been globally networked and produces complex products in which people from a wide range of organizations work together in innovative ways. This industry is therefore particularly well suited as a pioneer for developing cross-company applications.

Embedded in “DEPOT – Digital Development, Production, Logistics and Transport in the context of Aerospace Industry 4.0” led by Airbus, Favendo dedicated itself to the project “Indoor Asset Tracking” within the project. The overall objective of the DEPOT project was to accompany the complete product creation process from design to production at the supplier and finally to manufacturing at the manufacturer on the path of digitalization.

DEPOT was funded by the German Federal Ministry for Economic Affairs and Energy based on a resolution of the German Bundestag. In addition to Favendo, the collaborative partners included Airbus Operations GmbH, Liebherr-Aerospace Lindenberg GmbH, SAP SE, Fraunhofer Gesellschaft zur Förderung der angewandten Forschung e.V., TU Hamburg, Diehl Aviation Gilching GmbH and DAKO GmbH.

The high degree of networking of information and processes requires that in the future, processes and value creation no longer be viewed in isolation within the company, but rather networked with suppliers and customers. Today, the focus of processes and optimization is on the company itself, and communication with external partners is bilateral and process-specific. In the future, however, the network will be at the center of the processes. Thus, communication and processes will run across companies. On another level of supply chain management, which is not digital, it is about practical things such as defining the type of transport and the transport route. Here, load carriers and packaging concepts for complex components are developed and manufactured on an item-by-item basis. At Airbus, for example, an enormous variety of item-specific steel and aluminum racks are used to hold the packaged items. These can only be used in part for several articles and are scalable to a small extent for different article quantities. Storing empty and loaded racks requires large areas at suppliers and at Airbus. Locating racks in these areas is at times very time consuming. Usually the planning of the allocation of load carriers to articles is done manually based on rack and article drawings.

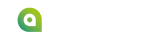

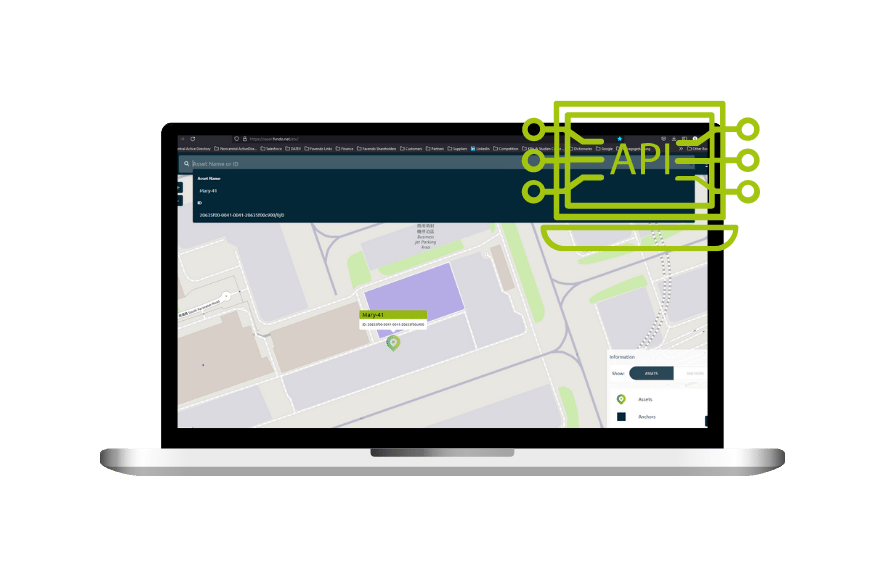

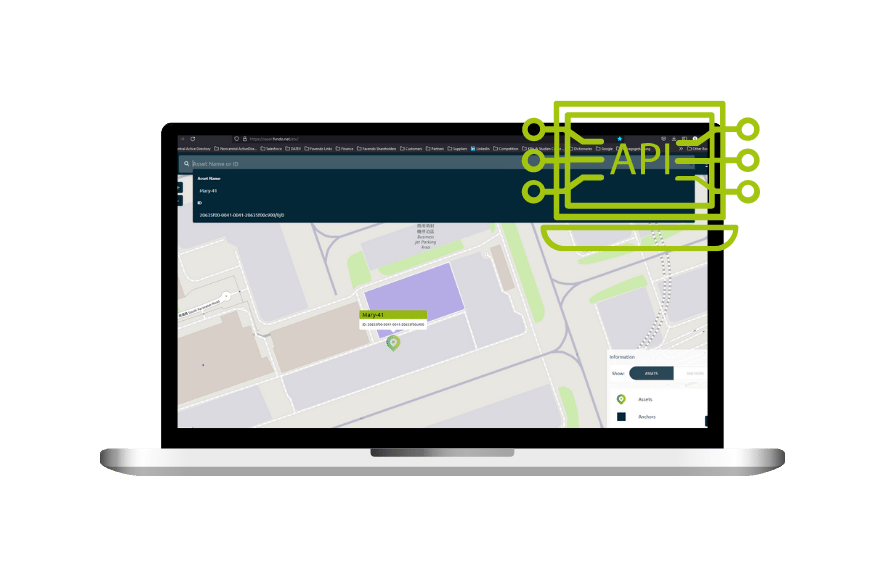

As part of DEPOT, Favendo has set up a Bluetooth Low Energy-based infrastructure for the precise location of load carriers (goods, production equipment, people) in an industrial production environment. The system architecture is scalable and can not only locate the objects, but also capture their elementary environmental data (temperature, air pressure, humidity, acceleration) and communicate them coupled to the position. The data collected by sensors is communicated in real time to partner systems (CRM or ERP systems, in this case SAP S/4HANA in particular), interpreted by them and processed.

The indoor asset tracking solution delivered by Favendo makes it possible to monitor every component in real time – from delivery to final assembly in production. This sets the foundation for “make-to-order” production planning and, for example, ramp-up in aircraft production. The integration of IoT data from research partners Favendo on the inside and DAKO on the outside enables near real-time visibility of position and part, component and product status.

These products were in use:

- converts the generated sensor status data into location data

- precise and reliable Real Time Location

- enables indoor positioning and navigation/wayfinding, proximity marketing and asset and person tracking

- Superior multi-scalable system architecture

- can be hosted on cloud or on premises

- powered over PoE, USB or AC

- small and discreet

- for industrial use or in hospitals

- standard JSON/REST push/pull API

- simple integration of location data in existing systems

- customizable

your personal contact person