Minera Antucoya is part of Antofagasta Minerals, Chile’s leading private mining group founded in Antofagasta, the copper mining capital of the world. The Antucoya mine opened in 2009, went into production in 2017 and is expected to produce 85,000 tons of copper cathodes per year. The raw material for copper production is oxide ore, which is mined in open pits. About 40% of the world’s copper deposits are located on Chilean territory. Copper production is thus the center and engine of the Andean country’s economy. In 2012, one third of the world’s copper production came from Chile. Copper exports account for more than half of all export revenues.

In order to optimize the productivity and utilization of machines and employees in open pit mining, the data obtained is needed above all in the “last mile” of the production process. The problem here is that in opencast mining/mining, work orders were previously passed on to employees in written/manual form. Accordingly, much was lost in the documentation and it was hardly possible to apply BI or AI programs to it. Additional difficulty: the environment, which is by nature highly ferrous and electromagnetic.

Favendo’s partner IGO therefore developed the IGAT platform, which digitizes the production steps of this very last mile and enables real-time measurement of productivity and displays it in a “Productivity Dashboard”.

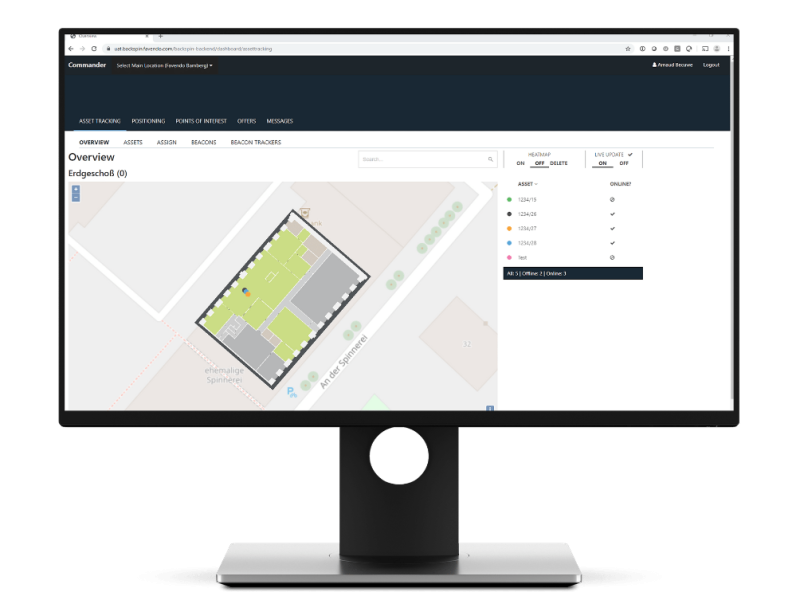

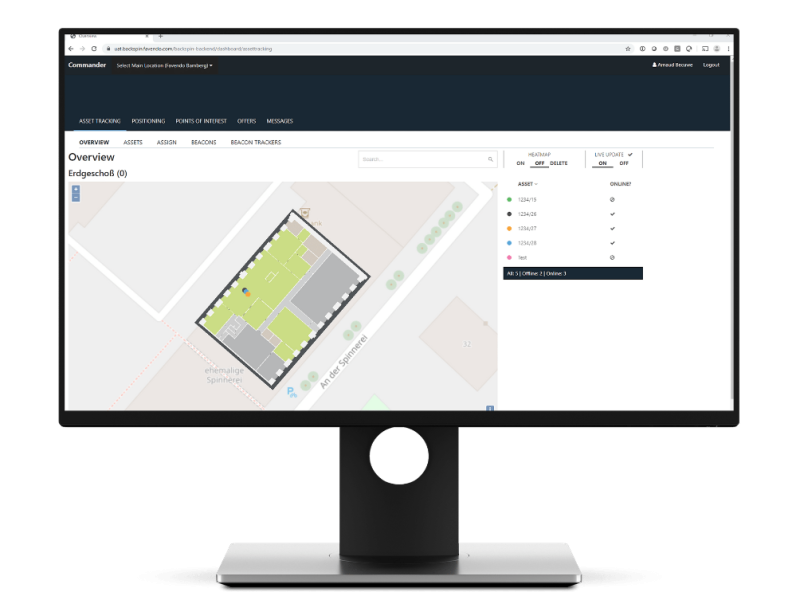

An important basis for meaningful results in this “Productivity Dashboard” is the position data of machines, equipment and employees. Favendo’s asset tracking solution comes into play to obtain this data. Equipment, vehicles and workers are tagged and tracked seamlessly inside and outside buildings in defined zones. The Favendo Positioning Engine calculates the position data and passes it to the IGAT platform via an interface.

For the harsh mining environment, some adaptation of the hardware was necessary to protect it against the ubiquitous red dust and to make it as durable as possible. For example, the Favendo Relay Compact Tracker Pro was equipped with a special housing that can withstand both heavy dirt and changes in air pressure.

Digitizing the last mile and eliminating paperwork resulted in a daily time savings of about one hour per technician. As a result, productivity increased by 14 percent for a 7-hour shift, while maintenance and repair costs dropped by 18 percent.

These products were in use:

- converts the generated sensor status data into location data

- precise and reliable Real Time Location

- enables indoor positioning and navigation/wayfinding, proximity marketing and asset and person tracking

- Superior multi-scalable system architecture

- can be hosted on cloud or on premises

In addition to the Smart Badges, the following tags were also used:

- Abeeway Micro Trackers

- Abeeway Compact Trackers

- Kontakt.io CT-18 Card Tags

Variety of tags suitable for the different assets to be tracked – from robust and resistant to small and practical to support accurate and continuous outdoor and indoor tracking.

- customized by Favendo for this use case

- dust-proof casing for harsh mining environment

- providing seamless indoor/outdoor tracking

- large coverage area

- Complies with the specifications set by the LoRa Alliance

your personal contact person

Let’s find an RTLS solution for your use case!

Send us a message and we will get in touch with you.